solidworks sheet metal chassis In this tutorial, I am going to explain how to create Sheet Metal Components with Top-Down Approach. Also, I am goin explain how to used "EDIT mode" in assembly for modifying one component with. If there's no ground in the junction box, you go without, or pull a grounding wire. A newly pulled grounding wire is permitted by NEC to take a different path than the current carrying wires (neutral and hot) and can be bonded to other grounding wires on the way back to the breaker box.

0 · Solidworks tutorial

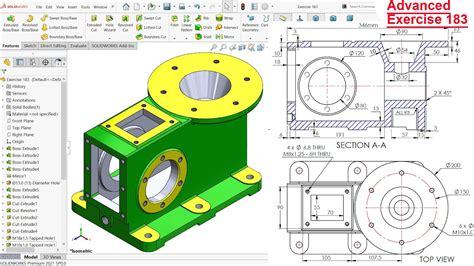

1 · Solidworks Sheetmetal Design and Developments

2 · SolidWorks Sheet Metal Tutorial # 348 : Power Supply Chassis

3 · SolidPractices: Sheet Metal

4 · Rackmount Chassis Design In SolidWorks Sheet Metal

5 · Creating a Sheet Metal Part Using Round Bends

6 · Creating a Sheet Metal Drawing

7 · Completing the Sheet Metal Drawing

8 · Building a chassis

I would say it can go in a closet. Otherwise would a junction box be allowed in a storage closet. I think the issue is live parts and overcurrent devices. A media cabinet is not a .

solidworks tutorial 348 power supply withsheet metal tool commands,borrowed from T.E. SolidWorks Learning course (voice): https://www.youtube.com/playlist?li. in this tutorial video i will sketch Power box chassis in Solidworks with the help of sketch and Sheet metal tools.I hope you like it.Please subscribe our ch. In this tutorial, I am going to explain how to create Sheet Metal Components with Top-Down Approach. Also, I am goin explain how to used "EDIT mode" in assembly for modifying one component with.In this movie, we're going to go through the basic steps required to build a sheet metal chassis with several parts all created in the same parts file.

The Solidworks Sheetmetal Design and Developments software is a powerful tool for designing and developing sheet metal products with ease and precision. Whether you are creating simple brackets or complex enclosures, .SOLIDWORKS has specific sheet metal features that allow the creation of sheet metal bodies very quickly. However, in some circumstances, when the design demands certain types of .

Building a chassis. - [Narrator] In this movie, I wanna show you how we can create a multi-body sheet metal part that will automatically update when we change the individual components, so.Under Tangent edges, select Visible, and click OK. Click Make Drawing from Part/Assembly (Standard toolbar) or File > Make Drawing from Part, then click OK to open a drawing sheet. .

To create a sheet metal part with round bends: Sketch a closed or open profile. Create a thin feature part. Depending on the type of profile, you can use tools such as Shell or Extruded .A flat pattern view is automatically added in the PropertyManager when you create a sheet metal part. Click Model View (Drawing tab). Click . Under Orientation, in More views, select (A) Flat .I am making a chassis out of sheet metal 1.5mm thick with a corner radius of 0.75mm and I want to weld down the torn corners. I have tried to do this with the weld corner tool however, it wont work. When I click on a surface with the weld corner tool no preview appears and fails to work when I press the green tick.

in this tutorial video i will sketch Power box chassis in Solidworks with the help of sketch and Sheet metal tools.I hope you like it.Please subscribe our ch.You can create notches across bends in flattened sheet metal parts. In manufacturing, bend notches help manufacturers determine where to put the press brake. You can use notch features on all bends so the bending operator can then use them to .Learn the basics of creating multiple parts in one operation, using the demo chassis. . Ex_Files_SOLIDWORKS_Sheet_Metal_Design.zip Download the exercise files for this course. Get started with a .

Yes, SolidWorks is an excellent tool for designing and building metal PC cases. Its sheet metal features and thermal analysis capabilities make it well-suited for your custom case project. I'd recommend exploring SolidWorks to leverage its specialized tools and optimize your design for manufacturing and cooling.For example, Designer Chet Roe, who began working at PS Audio as an intern, uses SOLIDWORKS sheet metal design tools to save time whenever custom chassis that require modification of standard-sized chassis are required. “SOLIDWORKS saves time whenever we need to customize a chassis or fabricate sheet metal, which happens whenever we’re .

The individual sheet metal parts are inserted into the weldment part. However, if the weldment contains extrusions then those compoments are all created inside the weldment due to the ease of generating a cut list, creating paths using 3-D sketches, and .

2) Best Approach To Modeling Sheet Metal Bodies SOLIDWORKS has specific sheet metal features that allow the creation of sheet metal bodies very quickly. However, in some circumstances, when the design demands certain types of geometries, the user has the option to use non-sheet metal feature tools and then use theFor Sheet Metal users, the new features in SOLIDWORKS 2025 are sure to excite. In addition to never-before-seen bend notches, the list of enhancements to existing features is long, so let's dive in. Sheet Metal and Weldment Bodies. This part contains a mixture of . we will learn sheet metal basic features like Base Flange,Edge Flange ,Sketched bend and Extruded Cut in Solidworks sheet metal.1)Solidworks tutorial for Beg.

Solidworks tutorial

Design hub this series for sheet metal designer, hope so it helps you allplease support on patreonhttps://www.patreon.com/designhub12

Search for jobs related to Sheet metal vehicle chassis design solidworks or hire on the world's largest freelancing marketplace with 24m+ jobs. It's free to sign up and bid on jobs.#solidworkstutorials#solidworkstips#solidworkstricks#solidworks#autocad#autocadtutorials#inventor#solidedge#mechanicaldesign#3ddesign#mechanicaldrawing#mecha.In this video, I am going to explain about Dimple Feature and its Design Guidelines👉Download the Drawing file from below Link for Learning and better unders.

Chassis for Automatic Voltage Regulator by Sheet Metal (SolidWorks 2014 Tutorial) Serial No. 17. Chassis for Automatic Voltage Regulator by Sheet Metal (SolidWorks 2014 Tutorial) Inside this video, viewers will watch full detailed process of creating this model through SolidWorks Sheet Metal design functionality.

Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody . The streamlined study setup in SOLIDWORKS Simulation requires the geometry to be created using SOLIDWORKS sheet metal entities. This can be accomplished by creating a new model constructed with sheet metal .Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody . Like team 148’s robot chassis for example! . Be A Better Machine Designer with SOLIDWORKS Sheet Metal - June 22, 2020; Categories: Design, SOLIDWORKS, SOLIDWORKS Simulation, Tips & Tricks. Tags: optimization, Topology, Topology Study, weight reduction. Search. Search for: Search.

The power supply chassis that I have designed on SolidWorks for GrabCAD is a robust and sturdy component that ensures efficient power supply. Power supply chassis design using SolidWorks Tool Metal Sheet | 3D CAD Model Library | GrabCADSheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .

You can flatten all the bends of a sheet metal part at once. Creating a Sheet Metal Drawing. Now create a drawing of the sheet metal part. Start with an isometric view of the folded model, and then add a view of the unfolded model. Completing the Sheet Metal Drawing. Next, add a view of the unfolded model.

in this tutorial video i will sketch Power box chassis in Solidworks with the help of sketch and Sheet metal tools.I hope you like it.Please subscribe our ch.I have a round tube chassis I designed using 3D sketches and weldments. A lot of these weldments are off axis and it would be difficult to try to model sheet metal around/over/between them using the standard base and edge flange Features, especially since they are cylindrical weldments. What is going to be the easiest route to apply a .

Solidworks Sheetmetal Design and Developments

Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .

Approved Sheet Metal (ASM) excels at fabricating custom sheet metal chassis. We understand that many industries rely on precise, high-precision fabricated parts. Our team of dedicated sheet metal mechanics, laser operators, and programmers get it, we understand that speed and price won’t make a difference if the parts aren’t right.Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .

What if There Is No Ground Wire In Junction Box? The NEC expects consumers to ground their electrical systems, especially if those systems supply exceeds 120V. The NEC’s rulings will keep you safe.

solidworks sheet metal chassis|Completing the Sheet Metal Drawing